161

Robots Showcase / Re: TDS

« on: September 22, 2015, 08:47:26 AM »

Thanks guys,

looking good so far!

looking good so far!

|

This section allows you to view all posts made by this member. Note that you can only see posts made in areas you currently have access to. 161

Robots Showcase / Re: TDS« on: September 22, 2015, 08:47:26 AM »

Thanks guys,

looking good so far!

164

Real Robotics Discussion / Re: Design concept and internal check« on: September 02, 2015, 08:00:57 AM »

the drum supports should be forward of your expected point of impact so that you don't pull a frontie and eat the floor. at the very least they should be slightly forward of the axle

165

Robots Showcase / Re: TDS« on: September 02, 2015, 07:42:54 AM »

Running into some drive train issues so it looks like i'm going to miss barn battles this weekend =/ pretty much everything possible is wrong

-extended banebots shafts are the wrong size and i'm having difficulty turning them down -banebots hubs are the wrong bore and outer diameter -pulley belt is too short ~.~ On the good side with more filing and fitting I'll be spending all night drilling and tapping holes, then the frame is done, then I can start on the rack and pinion 167

Robots Showcase / Re: TDS« on: August 28, 2015, 10:14:50 AM »

Looks like blue saw came through for me, delivery by monday

I'm going to try and throw this thing together next week, convert it to a lifter and show up to barn battles for the 30lb sumo next weekend 168

Robots Showcase / Re: TDS« on: August 27, 2015, 07:54:35 AM »

Yes on both counts

In other news ruin snaps its weapon chains so I'm going to have to double strand it and use something else to return the hammer, order another sprocket and get clever, or turn it into a flipper. hrm =/ 169

Robots Showcase / Re: TDS« on: August 26, 2015, 02:30:01 PM »What bot did you have at Bot Blast? I feel really dumb right now. Didn't, I took my godson, I was the tall guy with the buffalo warmachine jersey whom Adrian was haranging all day  If blue saw comes through for me and my stuff comes in next week i'll be showing up at barn battles in PA next weekend Might throw together a 12pounder with some handiworks drills i have sitting around 171

Robots Showcase / Re: TDS« on: August 25, 2015, 08:50:16 AM »

Ordered the waterjet parts today so the design is largely finalized

ended up lengthening the frame a little, and designing the whole thing to be sawed down to ~2.5" tall for version 2, or another bot. 172

Robots Showcase / Re: TDS« on: August 19, 2015, 02:54:48 PM »

CF, UHMW baseplates/armor, screws, piston clevis, ect. ect. showed up this afternoon, solenoid should be in later today or tomorrow. Cad progress continues and it mostly wrapped up, weight seeming less and less dire as I continue to swiss cheesify parts, and my hammer support members probably dont need to be 3/4" thick, should have it ready for tweaking by early next month.

also ordered some ar400 shooting targets to chop up into various hammer heads

173

Robots Showcase / Re: TDS« on: August 18, 2015, 12:30:43 PM »i can't tell if your batteries are lipo. If they are you can't use them in a sportsman at franklin. venue won't allow it. LiFePo , I'm fine 174

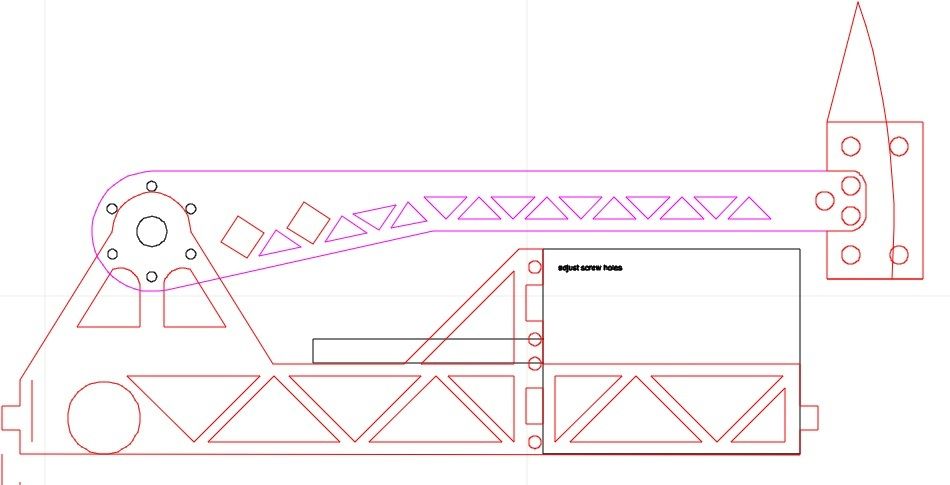

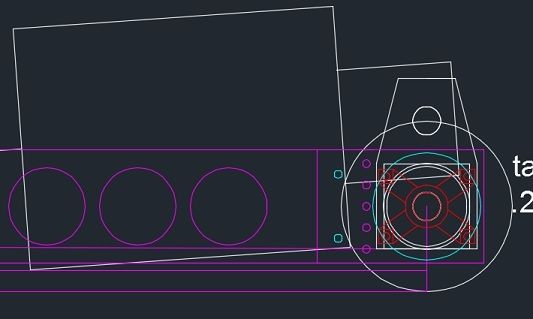

Robots Showcase / Re: TDS« on: August 18, 2015, 07:46:14 AM »Why do you have a receiver battery? Unless your ESCs don't have a BEC and you don't have a RadioShack nearby, you don't need it. People on the FB group were bitching and complaining that I couldn't use my old RCE battery eliminator circuit without blowing everything up because newer esc's aren't optically isolated so I figured I'd play it safe its like a quarter of an ounce to make sure my bot doesn't mushroom cloud. I'm aiming for franklin, my angle-iron-wedge-defense for these bullsh** sportsman notwedge bots got shot down because of course it did so now my plan is to make sure my first solid hit kills the bot Small CAD update for the hammer support and hammer arm, still needs some tweaking I just liked the triangle pattern  The open area on the main support will house the rack and pinion to actuate the arm. Not pictured which may not happen is there will be a AR400 cutting edge along the front of the hammer incase the head misses 176

Robots Showcase / Re: TDS« on: August 17, 2015, 12:00:58 PM »

Smashing if I can get away with it, the arm is setup to have interchangeable heads so that'll probably happen, if people start to bring judge plates I can go with a spike, I'd rather bend up someone's frame than pierce their expensive electronics box, this is sportsmans league after all not super serious mode.

Just about everything is ordered and the last should be here in the next few days, then its frame fabrication time, it should come together fairly fast. 177

Robots Showcase / Re: TDS« on: August 17, 2015, 08:58:06 AM »

Minor update, finally got most of the oddly shaped parts in and things are starting to come together CAD wise

Basic frame/body shape posted below, weight is going to be tight, everything not bearing stress from the hammer besides the front prow will be UHMW as weight is going to be very tight for V1 178

Robots Showcase / TDS« on: August 12, 2015, 03:53:51 PM »

So, i've been designing and building my first bot in quite a while, it will be a 30lb sportsman

via a challenge issued at botblast, it will be a pneumatic hammerbot. Since I dont have time to fabricate my own cylinder, I'm using a bimba 4" stroke cylinder I found on ebay  its rather big  okay its really big This will be run on HPA to a chain driven cam based rack and pinion mounting a ~18 inch arm Pseudo math that I may have done wrong because piston speed calculation is dicey has the hammer clocked in at 317mph at impact @200psi (everything is rated for 300psi) 2x banebots 16:1 's to 3" wheels 4wd (because 2wd is stupid) Much of the cad is unfinished so nothing fancy yet, a majority of the parts should be arriving by friday this week and the weird shaped stuff like the HPA tank can be measured properly at that time. I am currently super concerned that I am overweight, with a vast majority of the internals, and rounding up every part I am at 15.5lbs without a frame, hammer arm, screws, wires, ect. The problem is trying to house the gas tank and cylinder makes the frame gigantic (I was showing ~4lbs per frame member and i need 4) which has me gravitating towards blue saw waterjet 3/8" 6061AL or 1/2" or so UHMW instead of aluminium because weight. Another idea is to make a judge-style frame that is basically a big strong baseplate and a titanium shell, since I can't weld titanium it would be achieved with a bunch of aluminium bearing blocks. We'll see how the layout goes once everything comes in. The funny part is I know exactly how to get ruin V2 to work and be much lower profile (and have a proper 180+ degree hammer swing) but i'd never get it done in time for nerc franklin, so this is sort of a stopgap bot to find any problems that may arise running a hammer with 1700lbs of thrust 179

Real Robotics Discussion / Re: Robotics General Discussion Thread« on: August 10, 2015, 07:27:04 PM »I've noticed that, just my hammer arm was like $150 to do which I was expecting, but having a ton of frame members cut out of 3/8" was ~130 or somesuch, which is cheap! I know that applies to regular machining (I know what i'm doing here) but that isn't necessarily true for waterjet as its 2D and a lot of the settings you need to input can be pre-set or referred to a chart or table (there's only so many material and thicknesses you're cutting here) Don't get me wrong, its a pain in the ass, but it isn't facing all 6 sides of a block of metal and setting up a cnc by any stretch of the imagination. You're paying about 60 bucks for them to setup the machine for you, sure thats fine. that being said their prices are /really/ reasonable for large frame members and stuff, I was really impressed at what my frame might cost me (especially since they are providing the metal) I'd really appreciate an option of "get this sh** to me whenever you like for cheaper" where they could stuff my stuff in on the edge of someone elses work when they happen to be doing that material or something. But thats me being picky, i'll likely end up machining the hammer arm myself and doing it poorly since my mill only has a 11" or so travel. I'm probably going to use them for the frame, which will take some redesigning since i was planning on using 2" .125wall square tubing for the drive pods and spine, with waterjet i need to end tap so its going to have to be at least .375 thick 180

Real Robotics Discussion / Re: Robotics General Discussion Thread« on: August 10, 2015, 04:05:28 PM »

I've noticed that, just my hammer arm was like $150 to do which I was expecting, but having a ton of frame members cut out of 3/8" was ~130 or somesuch, which is cheap!

it seems like if you stay below 1/2" the price is pretty manageable. |